CNC Metal Cutting Machine Tools Market: An In-depth Analysis of Size, Share, Trends, and Growth

The CNC metal cutting machine tools market has witnessed remarkable evolution over recent years, characterized by significant growth in market size and expanding global share. Driven by rapid advancements in technology, increasing demand for precision manufacturing, and the rise of automation in industrial processes, the market trends point toward sustained upward momentum. From small-scale workshops to large industrial manufacturing units, CNC metal cutting machines have become indispensable tools, pushing the boundaries of efficiency and accuracy. The growth of this market is also propelled by the rising adoption of these tools across automotive, aerospace, electronics, and construction sectors, all demanding high precision and repeatability in metal cutting operations.

Understanding CNC Metal Cutting Machine Tools

CNC (Computer Numerical Control) metal cutting machines are advanced mechanical tools operated by computer systems to execute precise cutting, shaping, and machining of metal components. These machines replace traditional manual metal cutting tools by offering superior accuracy, efficiency, and flexibility. By automating the machining process, CNC metal cutting tools reduce human error, improve production speed, and allow for complex geometries that would be challenging or impossible to achieve manually. Popular CNC metal cutting machines include CNC milling machines, CNC lathes, CNC grinders, and multi-axis machining centers, each serving different metalworking needs.

Market Size and Share

The CNC metal cutting machine tools market size has been expanding steadily due to increasing industrialization, urbanization, and technological innovation. The surge in demand for lightweight yet durable metal parts in sectors like automotive and aerospace has boosted the need for precise cutting tools. Manufacturers are investing in state-of-the-art CNC systems to optimize production and reduce waste, further driving market expansion. Market share is highly competitive, with key players focusing on innovation, product diversification, and strategic collaborations to consolidate their presence globally. Countries with established manufacturing ecosystems, such as China, Germany, Japan, and the United States, dominate the market share due to their advanced industrial capabilities and adoption of automated machining technologies.

Current Trends Shaping the Market

Several emerging trends are shaping the CNC metal cutting machine tools market. One significant trend is the integration of Industry 4.0 technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and machine learning into CNC systems. These integrations enable predictive maintenance, real-time monitoring, and adaptive control, resulting in increased machine uptime and productivity. Another important trend is the development of high-speed and multi-axis CNC machines that enable complex part manufacturing with fewer setups, reducing production cycle times. Additionally, environmental concerns are steering the market toward energy-efficient CNC machines that minimize power consumption and reduce waste through better material utilization.

The demand for customized and small-batch production is also rising, prompting manufacturers to adopt CNC machines that offer greater flexibility and ease of programming. The advent of user-friendly software and touch-screen interfaces has made CNC machines accessible to smaller manufacturers, fueling market growth in developing economies.

Market Growth Drivers

The growth of the CNC metal cutting machine tools market is driven by several factors. The automotive industry's transition toward electric vehicles (EVs) requires precision metal parts with complex designs, fostering increased adoption of CNC machines. Aerospace and defense sectors, which demand extremely high accuracy and quality standards, are significant contributors to market growth. Furthermore, increasing automation in manufacturing plants worldwide to reduce labor costs and enhance operational efficiency strongly favors CNC tool adoption.

The rise in urban infrastructure projects, leading to demand for metal construction materials, further propels the need for CNC metal cutting tools. Additionally, the growing emphasis on quality control and product consistency encourages manufacturers to deploy CNC machines for their ability to maintain tight tolerances and produce identical components at scale.

Challenges and Market Restraints

Despite the promising outlook, the CNC metal cutting machine tools market faces some challenges. High initial investment costs for advanced CNC machines and maintenance expenses can deter small and medium-sized enterprises from adopting these tools. The requirement for skilled operators and programmers to manage CNC machines also limits market penetration in regions with a shortage of technical expertise.

Moreover, fluctuations in raw material prices and global supply chain disruptions can impact machine tool manufacturing and delivery timelines. Environmental regulations and compliance costs may also add to the operational burden on manufacturers.

Segmentation of the Market

The CNC metal cutting machine tools market can be segmented based on machine type, end-use industry, and geography. By machine type, it includes CNC milling machines, CNC lathes, CNC grinders, and others like EDM (Electrical Discharge Machines) and drilling machines. Among these, CNC milling machines and lathes hold the largest market shares due to their versatility and widespread application.

By end-use, the automotive industry remains the largest consumer, followed by aerospace, electronics, medical devices, and construction sectors. Each industry demands specific features and customizations, influencing product development and innovation trends in the market.

Regional Market Insights

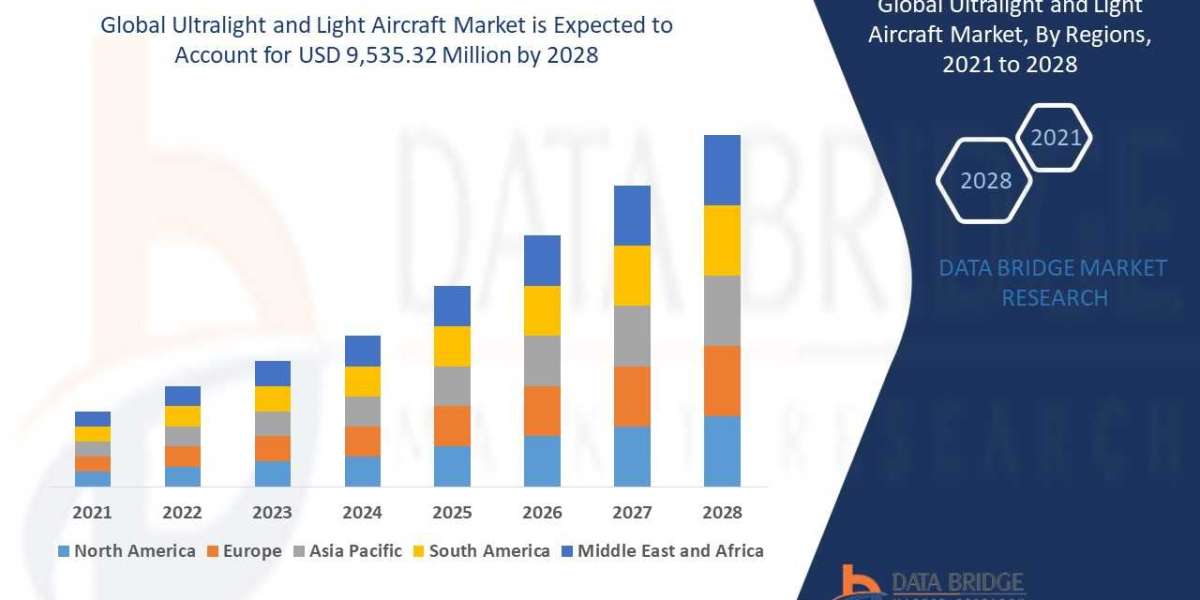

Regionally, Asia-Pacific is emerging as the fastest-growing market for CNC metal cutting machines, owing to rapid industrialization, increasing manufacturing activities, and government initiatives supporting automation. China, Japan, and India are leading contributors to this growth. Europe maintains a strong presence in the market with countries like Germany and Italy known for their high-quality CNC machines and strong automotive and aerospace industries.

North America continues to be a significant market due to advanced technological infrastructure, extensive RD activities, and strong industrial demand, particularly from the United States and Canada.

Technological Advancements

Technological innovation remains the cornerstone of growth in the CNC metal cutting machine tools market. The development of hybrid machines combining additive and subtractive manufacturing processes is gaining traction, allowing manufacturers to produce complex parts with minimal waste. The use of advanced materials such as ceramics and composites for cutting tools enhances durability and performance.

Automation and robotics integration with CNC machines enable seamless material handling and reduce human intervention. The emergence of cloud-based CNC machine monitoring systems allows remote diagnostics and performance optimization, enhancing operational efficiency.

Future Outlook

The future of the CNC metal cutting machine tools market looks promising, with ongoing research and development focusing on enhancing machine intelligence, precision, and energy efficiency. The increasing demand for smart factories and digital manufacturing environments is expected to accelerate the adoption of advanced CNC machines. The market will likely see more collaborations between machine tool manufacturers and software developers to create integrated solutions that simplify programming and improve user experience.

Emerging economies will continue to invest heavily in upgrading their manufacturing infrastructure, providing ample growth opportunities. As industries strive to meet stringent quality standards and reduce production costs, CNC metal cutting machine tools will remain a critical enabler of competitive manufacturing capabilities.