Understanding how a laser cleaner works and where it fits best in production environments can help businesses adopt it strategically for long-term efficiency.

Understanding the Function of a Laser Cleaner

A laser cleaner operates on the principle of laser ablation. The laser beam delivers concentrated energy to the surface, heating and vaporizing unwanted layers such as rust, paint, or oil without damaging the base material. This process is highly controlled and selective, allowing users to clean surfaces accurately at micro or macro levels depending on the application.

The core of this technology lies in its laser source, typically fiber, pulsed, or continuous wave. The cleaning process depends on the type of contaminant and substrate. By adjusting the pulse frequency, power, and scanning speed, the operator can fine-tune the removal depth and efficiency. The laser energy breaks the bond between contaminants and the surface, making the unwanted layer evaporate or turn into dust particles that can be vacuumed easily.

Unlike mechanical or chemical cleaning, laser cleaning does not produce secondary waste. The result is a clean, ready-to-process surface ideal for welding, coating, or inspection.

Industrial Importance of Laser Cleaning

In industrial environments, surface preparation and cleaning are essential before welding, painting, coating, or bonding. The laser cleaner ensures the base material remains intact while contaminants are effectively removed. Industries such as aerospace, automotive, shipbuilding, electronics, and power generation rely on this process to maintain precision and quality.

In aerospace manufacturing, components like turbine blades and molds require precise cleaning without altering their structural integrity. A laser cleaner delivers that precision, ensuring that sensitive parts remain undamaged. In the automotive sector, it is widely used for rust removal, paint stripping, and pre-weld preparation. For heritage and cultural preservation, laser cleaning provides a gentle approach to restoring metal and stone surfaces without affecting their historical details.

The non-contact nature of laser cleaning also makes it ideal for delicate or complex surfaces where traditional cleaning could cause mechanical stress or residue buildup.

Technology Behind a Laser Cleaner

A modern laser cleaner typically consists of several critical components:

Laser Source: Provides the energy beam used for ablation.

Scanner Head: Directs the beam to the cleaning area.

Cooling System: Maintains temperature stability.

Control Unit: Allows operators to adjust power, frequency, and scanning speed.

Safety Enclosures and Filters: Protect users from radiation and collect debris.

The technology utilizes specific wavelengths that target contaminants more efficiently. Shorter wavelengths are better for thin layers, while longer wavelengths are effective for thick coatings or rust. Laser power ranges from 20W to several kilowatts, allowing for flexibility across applications — from fine restoration to heavy industrial cleaning.

Surface Compatibility

A laser cleaner can be used on metals, ceramics, composites, and even some polymers. Its adjustable energy output allows it to handle materials ranging from soft aluminum to hardened steel. In electronics, it removes oxides from contacts; in tooling, it cleans molds without damaging their texture.

The versatility of laser cleaning enables its use in both production and maintenance settings. For instance, in mold manufacturing, residue and carbon buildup can be removed instantly without dismantling the mold. This reduces downtime and enhances productivity.

Environmental Perspective

A significant appeal of the laser cleaner is its environmentally responsible operation. Unlike chemical cleaning, which involves solvents and generates hazardous waste, laser cleaning produces minimal emissions. The vaporized particles are captured by filtration systems, and there is no need for disposal of contaminated liquids or abrasives.

This eco-friendly approach aligns with global sustainability goals, making it an attractive option for companies aiming to reduce their environmental footprint. In addition, it helps workplaces maintain safer conditions since operators are not exposed to harmful substances.

Application in Modern Manufacturing

Manufacturers adopt laser cleaners for tasks that demand consistency, accuracy, and repeatability. In welding operations, laser cleaning prepares surfaces by removing oxides and contaminants, ensuring a strong bond. In coating applications, it removes paint or residues to create a clean base for re-coating or adhesive bonding.

In heavy industries such as shipbuilding or pipeline maintenance, corrosion removal using laser cleaning is far more efficient than sandblasting. It eliminates rust quickly while keeping the substrate intact, which helps extend the lifespan of metal structures.

The process is also used in electronic manufacturing, where precision cleaning of circuit boards and connectors ensures high conductivity and product reliability.

Cost and Efficiency Considerations

A laser cleaner represents a long-term investment rather than a consumable-based process. Once installed, the operational costs are relatively low since it does not require chemicals, abrasives, or replacement parts. The power consumption varies based on the system size, but the efficiency and speed of cleaning make up for the initial investment.

Automation integration is another major benefit. Laser cleaners can be connected with robotic arms and CNC systems to perform cleaning operations with precision and repeatability, especially in high-volume production lines.

The maintenance of a laser cleaner is straightforward, focusing mainly on keeping the optics clean and ensuring the cooling system functions correctly.

Safety and Operational Guidelines

Operating a laser cleaner requires adherence to safety protocols. The laser beam, though highly effective for cleaning, poses risks if mishandled. Operators should wear protective eyewear suitable for the laser wavelength being used and ensure that reflective surfaces are handled with caution.

Modern systems come equipped with safety interlocks, enclosed chambers, and fume extraction systems that maintain air quality. Regular calibration and inspection ensure optimal performance and safety compliance.

Adoption Trends Across Industries

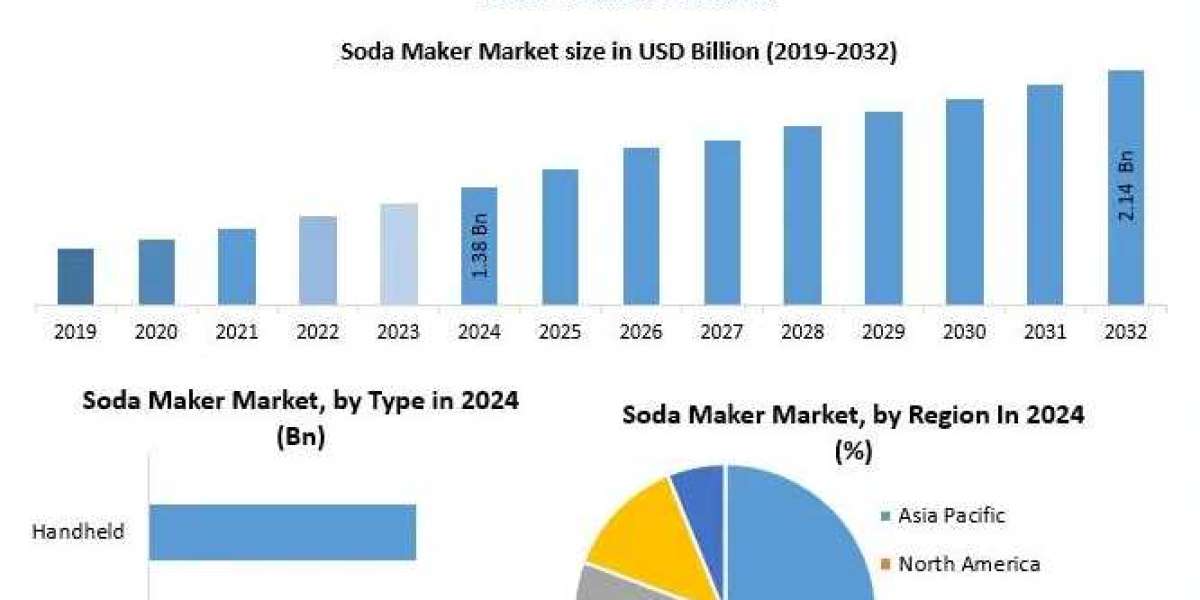

Globally, the adoption of laser cleaners continues to grow due to their versatility and cost-saving potential. Small workshops and large manufacturers alike are turning toward this technology to replace traditional cleaning systems. The trend is particularly strong in Europe and Asia, where environmental regulations are pushing industries to seek cleaner technologies.

The technology is also gaining traction in sectors like renewable energy, where components such as wind turbine parts and solar panel frames require precise and residue-free surfaces.

Future of Laser Cleaning Technology

As innovation continues, laser cleaners are becoming more compact, energy-efficient, and user-friendly. Future developments focus on higher power density for faster cleaning, improved control systems for automation, and multi-wavelength configurations for different materials. The industry is moving toward plug-and-play portable units that make on-site cleaning easier and faster.

Integration with smart sensors and digital monitoring systems will also enable real-time feedback on cleaning depth, temperature, and process stability. This advancement will help industries maintain consistent quality and reduce human error.

Final Thoughts

The laser cleaner stands as one of the most effective and sustainable technologies for modern surface treatment. Its ability to remove contaminants precisely without damaging the base material has reshaped industrial cleaning standards. From manufacturing to restoration, it supports cleaner, faster, and safer processes. As industries continue to prioritize sustainability and precision, laser cleaning will remain a key tool in ensuring product reliability, performance, and environmental compliance.