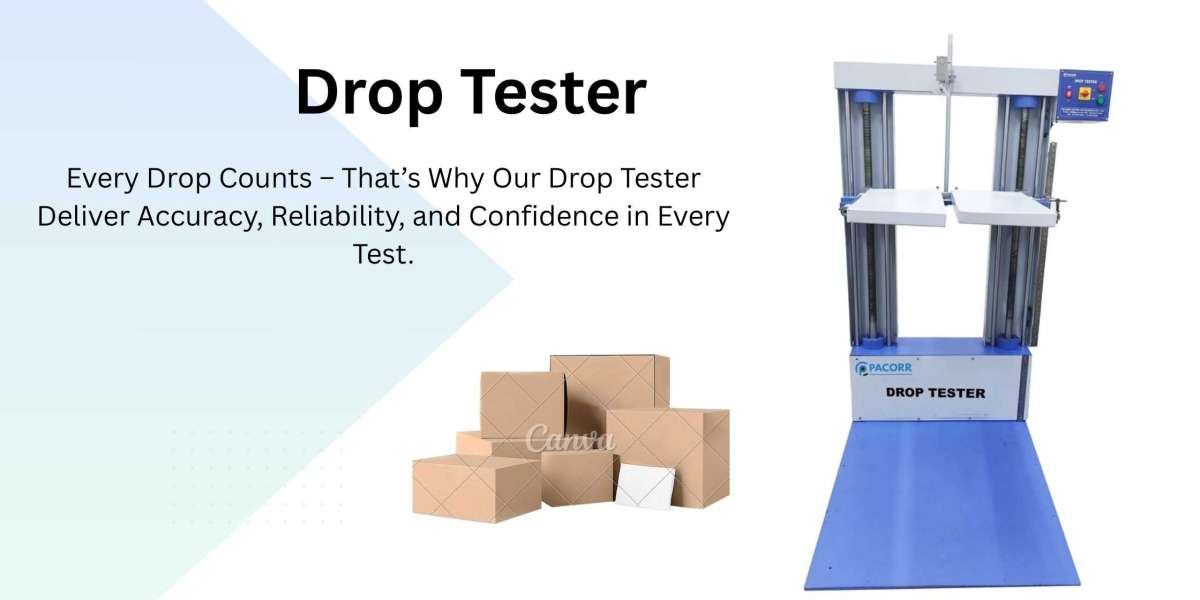

To address this, Pacorr’s Drop Tester provides manufacturers with a reliable solution to evaluate the impact resistance of their products and packaging. Our Drop Tester simulates the shocks and drops that occur during shipping, ensuring that your products are well-protected and ready for the journey.

What is a Drop Tester?

A Drop Tester is a precision testing machine designed to simulate the impact that products and their packaging face during handling and transportation. The device works by dropping a product from a specific height onto a surface, replicating the conditions it may encounter in the real world. By testing products under controlled conditions, the Drop Tester provides valuable data about their ability to withstand shocks, helping manufacturers assess the durability and integrity of their packaging and products.

Why is a Drop Tester Important?

Simulates Real-Life Scenarios: The Drop Tester replicates the forces your products are exposed to during shipping, giving you an accurate understanding of their durability in real-world conditions.

Minimizes Damage and Costs: By identifying weak points in your product design or packaging, the Drop Tester helps you reduce the likelihood of damage during transit, saving you from costly returns and improving customer satisfaction.

Enhances Packaging Design: Regular testing with a Drop Tester allows you to refine your packaging, ensuring that your products are protected throughout the shipping process.

Key Features of Pacorr’s Drop Tester

Adjustable Drop Heights: Pacorr’s Drop Testing allows you to adjust the drop height, so you can simulate various real-world impact scenarios based on your specific product requirements.

Precise Impact Measurement: The tester provides accurate and consistent data, helping you assess the resilience of your products and packaging materials under impact.

Versatility Across Industries: Whether you’re testing electronics, automotive parts, packaging materials, or food products, the Drop Tester is adaptable to a wide range of applications.

Simple and Efficient Operation: Designed with ease of use in mind, Pacorr’s Drop Tester requires minimal training and ensures quick, efficient testing with clear results.

Applications of the Drop Tester

Packaging Industry: Ideal for testing the durability of packaging materials like boxes, plastic wraps, and pallets, ensuring that products are well-protected during shipping.

Electronics Industry: Essential for testing the impact resistance of electronics, such as smartphones, laptops, and other delicate devices, ensuring they remain undamaged during transport.

Automotive Industry: Helps test automotive components to ensure they are resilient enough to withstand the impact of transportation without damage.

Food Beverage Industry: Ensures the packaging for food and beverage products is strong enough to endure shipping and handling, preventing any potential damage or contamination.

Compliance with Industry Standards

Pacorr’s Drop Tester meets key international standards to ensure that your testing process is both reliable and compliant. These include:

ASTM D5276 – Standard Test Method for Drop Test of Loaded Containers by Free Fall

ISO 2248 – Packaging: Complete, Filled Transport Packages, Drop Test

By adhering to these standards, Pacorr’s Drop Tester ensures consistent and high-quality results.

Conclusion

At Pacorr, we understand that product durability is essential to your business success. Our Drop Tester Price helps you ensure that your products and packaging can withstand the impact and stresses of shipping, providing you with the peace of mind that your products will reach their destination safely. Whether you’re in electronics, automotive, packaging, or food and beverage, Pacorr’s Drop Tester is the ideal solution to protect your products and improve the efficiency of your packaging design.