Double Wall Fabric Manufacturers have become increasingly relevant in today's advanced material markets. These producers supply a unique textile that’s engineered for strength, stability, and versatility. But beyond the factory gate, it’s the capabilities that make it a preferred solution in industries ranging from marine construction to aerospace and inflatable products.

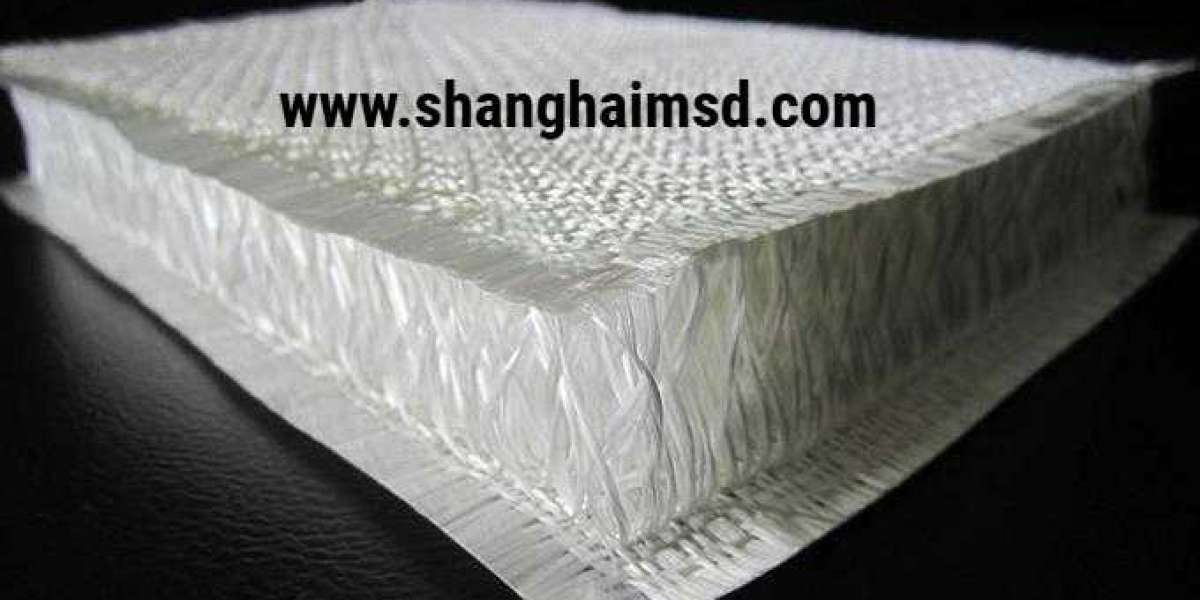

That also known as drop stitch fabric, consists of two layers of fabric connected by thousands of vertical yarns. When inflated, these yarns hold the top and bottom layers together, allowing the fabric to maintain a flat, rigid surface. This structural innovation enables the creation of lightweight yet high-strength products, including inflatable paddle boards, boat floors, air mattresses, and even portable tents.

What sets it apart from traditional materials is the perfect balance between portability and durability. The material can be deflated for compact storage and quickly reinflated when needed, making it ideal for products that require both strength and flexibility.

Key Advantages and Technical Features

One of the standout characteristics of this textile is its high-pressure tolerance. Unlike standard inflatable materials that may only handle low pressure, double wall fabric can support internal pressures of up to 15 PSI or more. This gives it an edge in applications where stability and firmness are crucial.

Moreover, it offers excellent resistance to wear, tear, UV exposure, and moisture, making it suitable for prolonged outdoor use. Manufacturers often add coatings or laminate finishes to enhance these protective properties. As a result, the fabric maintains performance and appearance even under demanding conditions.

Applications Across Industries

The use of double wall fabric extends beyond recreational gear. In the medical field, it’s used in inflatable medical beds and rehabilitation devices. In architecture, it's utilized in temporary inflatable structures that are easy to transport and quick to assemble. The military sector also benefits from its strength-to-weight ratio, integrating it into deployable shelters and floating bridges.

Its combination of strength, lightness, and ease of handling is driving innovation across sectors, inspiring designers and engineers to push boundaries and create products that were once considered impractical or impossible with traditional materials.

Conclusion

While Double Wall Fabric Manufacturers are at the forefront of production, it is the vast potential of the fabric that truly deserves recognition. With increasing demand for adaptable, high-performance materials, wall fabric is set to play a crucial role in shaping future solutions across diverse industries. To explore more about product options and technical specifications, visit shanghaimsd.com .