In the realm of modern manufacturing and heavy industry, surface cleaning is no longer a secondary process—it’s a vital step that ensures product quality, equipment longevity, and operational efficiency. Among the many technologies revolutionizing this space, the industrial laser cleaner has emerged as a standout solution, transforming the way companies approach rust removal, paint stripping, and contaminant elimination.

The Science Behind Laser Cleaning

Laser cleaning operates on the principle of laser ablation. A highly concentrated beam of light targets unwanted substances such as rust, oil, oxide layers, or paint. The energy from the laser heats and vaporizes the material without damaging the underlying surface. This method not only reduces wear and tear but also eliminates the need for abrasive media or harsh chemicals typically associated with traditional cleaning methods.

Industrial Applications: Clean Without Compromise

From automotive to aerospace, industries are investing in industrial laser cleaner systems due to their speed, safety, and environmental benefits. Unlike sandblasting or chemical cleaning, laser technology ensures high precision and minimal residue, making it ideal for tasks that require careful material handling. Metal fabrication shops often rely on laser cleaners to prep surfaces before welding or coating, improving bond strength and reducing defects.

The technology is also suitable for historical preservation, where delicate surfaces must be cleaned without damaging underlying materials. Laser cleaning removes decades of corrosion and dirt without leaving scratches or residue—a feat unmatched by conventional methods.

Efficiency Meets Sustainability

In an age where sustainability matters more than ever, laser cleaning stands out as an eco-friendly option. By eliminating the need for chemicals and reducing waste production, laser systems contribute to greener industrial practices. Additionally, operators benefit from cleaner working environments, as there's minimal airborne dust or fumes during operation.

One significant advantage is the reduced maintenance cost. Traditional cleaning equipment often requires frequent replacement of nozzles, media, or filters. With laser systems, the longevity of components is considerably higher, saving both time and money over the long term.

Why Choose LaserCleaner?

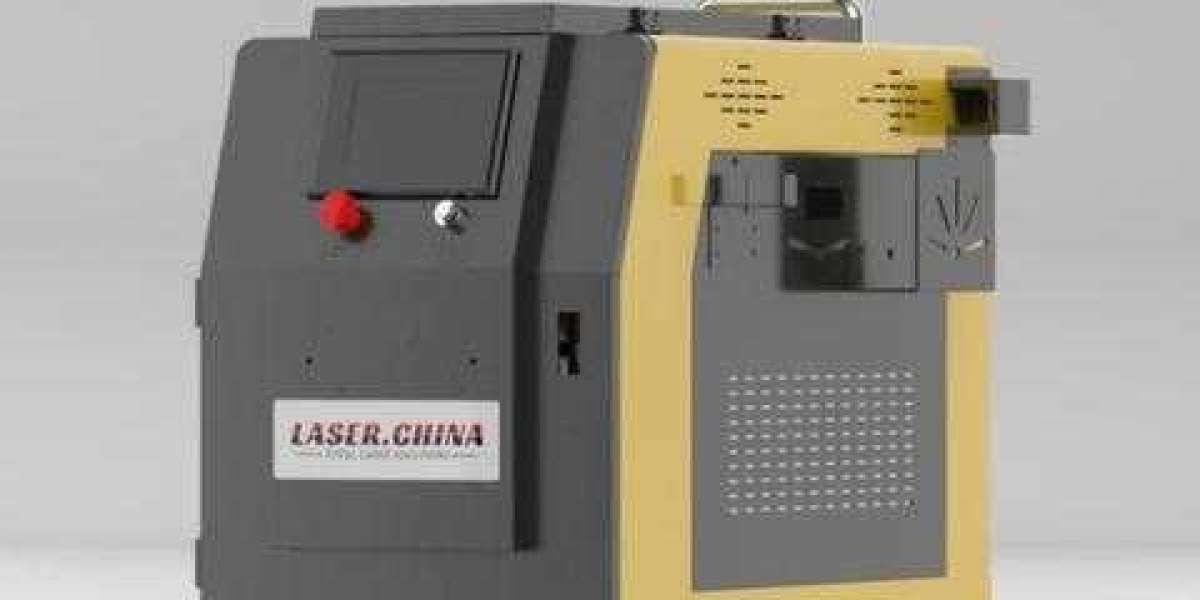

Companies exploring next-gen solutions are turning to LaserCleaner—a leader in advanced laser cleaning systems. Their equipment is designed for rugged industrial use, ensuring maximum output and reliability. With customizable configurations, LaserCleaner supports various industry-specific needs, from delicate precision to high-powered industrial strength.

Whether you're a small manufacturer or a global enterprise, investing in cutting-edge technology like an industrial laser cleaner can lead to significant gains in productivity and quality assurance. LaserCleaner provides comprehensive support, including installation, training, and maintenance, giving clients the confidence to adopt laser-based solutions at scale.

Future-Proofing Your Operations

As industrial standards continue to evolve, embracing technology that aligns with environmental regulations and safety protocols becomes imperative. Laser cleaning technology not only meets but often exceeds these expectations. By integrating such systems into your workflow, you're not just improving your operations—you're future-proofing them.