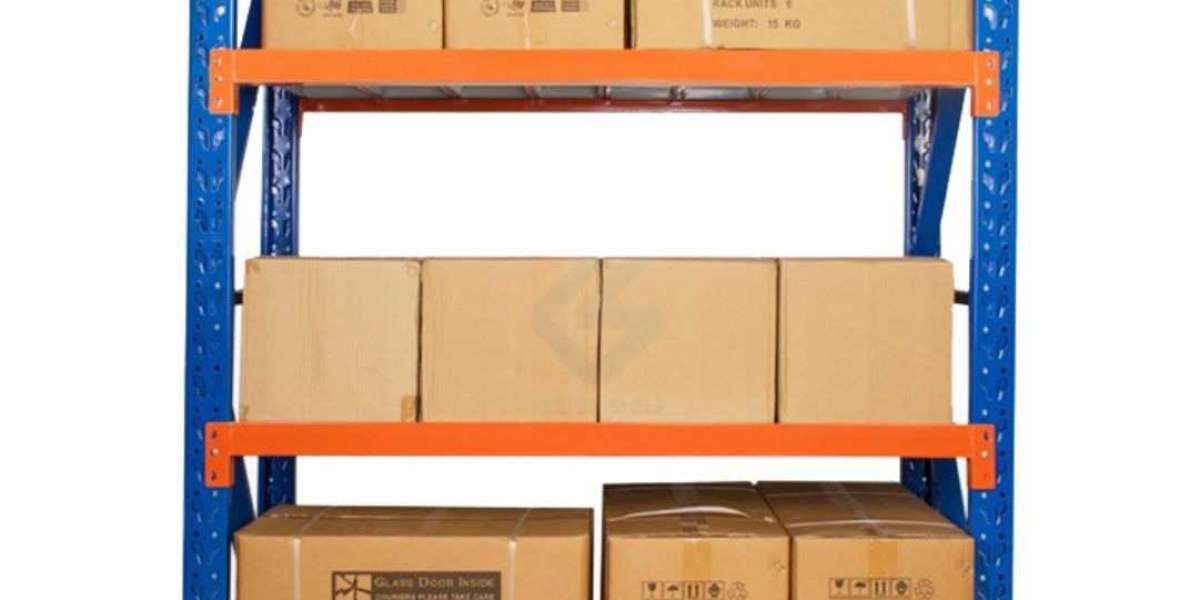

The Ultimate Guide to Packing Store Racks for Industrial Use

Efficient storage is crucial for any warehouse, factory, or logistics center. A well-designed packing store rack ensures organized inventory, maximizes space, and improves workflow efficiency. In Pakistan, Bari Engineering provides top-tier industrial packaging storage rack solutions tailored to meet diverse business needs.

Why Invest in a Packing Store Rack?

1. Optimizes Warehouse Space

A packing store rack utilizes vertical storage, allowing businesses to store more items in limited spaces. This is especially beneficial for warehouses with high inventory turnover.

2. Enhances Inventory Management

With designated storage slots, tracking and retrieving packed goods becomes faster and more accurate, reducing operational delays.

3. Improves Workplace Safety

Properly stored packaging materials prevent clutter, minimizing tripping hazards and ensuring a safer work environment.

4. Increases Operational Efficiency

Organized storage means quicker access to materials, reducing downtime and boosting productivity in packaging and shipping processes.

Types of Industrial Packaging Storage Rack Solutions

1. Pallet Racking Systems

Ideal for heavy-duty storage, pallet racks support bulk loads and are commonly used in large warehouses.

2. Cantilever Racks

Perfect for storing long or bulky items like pipes, lumber, and large packaging materials.

3. Mobile Shelving Units

Space-saving racks on wheels that can be compacted when not in use, ideal for facilities with limited floor space.

4. Mezzanine Floor Racking

Multi-level storage solutions that maximize vertical space, often used in high-ceiling warehouses.

Key Features of Bari Engineering’s Packing Store Rack in Pakistan

1. Heavy-Duty Construction

Our industrial packaging storage racks are built from high-grade steel, ensuring durability under heavy loads.

2. Adjustable Shelving

Customizable shelf heights allow businesses to store different-sized packaging materials efficiently.

3. Easy Accessibility

Designed for quick loading and unloading, our racks streamline warehouse operations.

4. Corrosion Resistance

Treated with anti-rust coatings, our racks withstand humid and high-moisture environments, ideal for Pakistan’s climate.

How to Choose the Right Packing Store Rack

1. Assess Your Storage Needs

Determine the weight, size, and volume of items to be stored to select the appropriate rack type.

2. Evaluate Available Space

Measure your warehouse dimensions to ensure the rack fits without obstructing workflows.

3. Consider Load Capacity

Choose racks with weight limits that match your inventory requirements to prevent overloading.

4. Prioritize Accessibility

If frequent access is needed, opt for open-style racks or mobile units for better maneuverability.

FAQs About Packing Store Racks

1. What is the maximum weight a packing store rack can hold?

Weight capacity varies by design, but Bari Engineering’s racks can support up to several tons, depending on the model.

2. Can packing store racks be customized?

Yes! We offer tailored solutions, including adjustable shelves and modular expansions to fit specific needs.

3. Are these racks suitable for outdoor use?

While primarily designed for indoor use, we also provide weather-resistant racks for semi-outdoor applications.

4. How do I maintain my packing store rack?

Regular inspections, cleaning, and tightening of bolts will ensure long-term durability and safety.

5. Where can I buy a packing store rack in Pakistan?

Bari Engineering supplies high-quality industrial packaging storage rack solutions across Pakistan. Contact us for a quote!

Conclusion

Investing in a high-quality packing store rack is essential for optimizing warehouse efficiency and safety. Bari Engineering offers reliable industrial packaging storage rack solutions in Pakistan, designed for durability, flexibility, and maximum space utilization. Whether you need heavy-duty pallet racks or compact mobile shelving, we have the perfect solution for your business.

Upgrade your storage system today and experience smoother, more efficient operations!