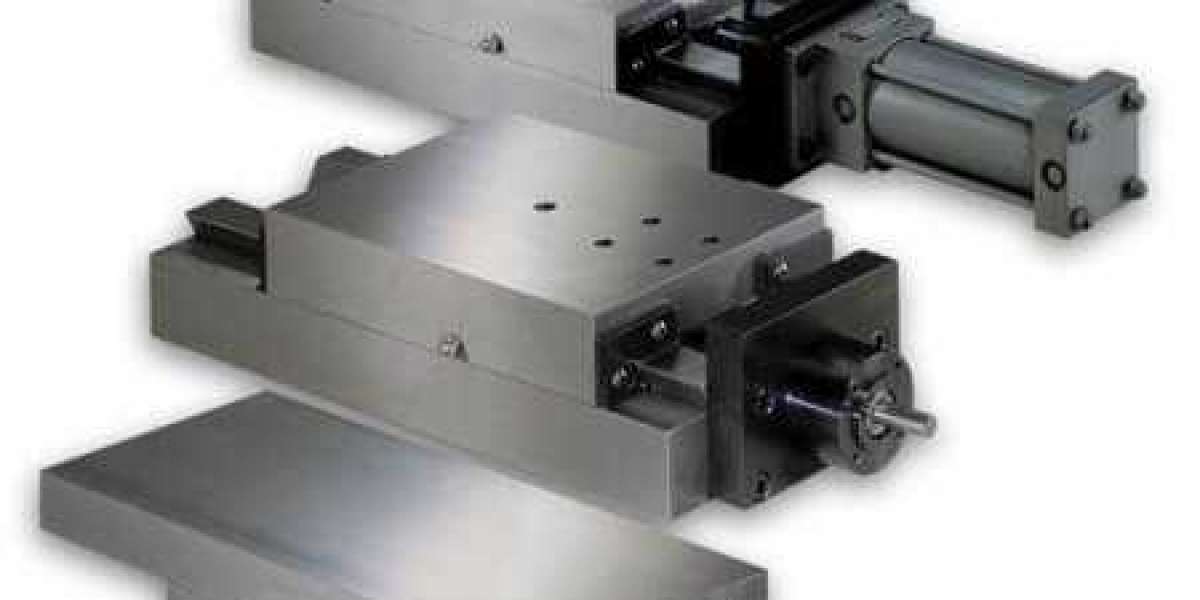

Gilman Precision designs and manufactures dovetail slides engineered to deliver smooth, stable, and accurate linear motion for a wide range of industrial applications. Known for their rigidity, durability, and long service life, dovetail slides are an ideal choice for engineers seeking a cost-effective and dependable solution for controlled linear movement. Whether used in CNC machines, automation systems, or heavy-duty industrial equipment, Gilman’s dovetail slides provide superior performance that meets demanding manufacturing requirements.

Advanced Engineering for Dovetail Slides

Precision-Ground for Smooth, Stable Motion

Gilman’s dovetail slides are meticulously machined and precision-ground to ensure stable linear motion with minimal play. Their design provides maximum surface contact between the moving and stationary components, which enhances rigidity and improves load-carrying capacity. This makes dovetail slides an excellent choice for applications requiring consistent accuracy under heavy loads.

Long-Lasting Durability

With a robust construction and high-quality materials, dovetail slides are built to withstand harsh industrial environments. They are designed to resist wear and maintain smooth motion over extended periods of use. Regular lubrication and simple maintenance keep these slides functioning efficiently for years, making them a cost-effective linear motion solution.

Benefits of Dovetail Slides

High Rigidity for Heavy Loads

One of the key advantages of dovetail slides is their ability to maintain stability under heavy-duty applications. The wide contact surfaces distribute forces evenly, reducing deflection and improving positioning accuracy even when subjected to substantial loads.

Cost-Effective Linear Motion Solution

Compared to other linear motion technologies, dovetail slides offer a simple yet reliable design with fewer components, resulting in lower costs for manufacturing and maintenance. This makes them ideal for a variety of machine tools and industrial equipment.

Easy to Maintain

Because dovetail slides have a straightforward mechanical design, they are easy to service and maintain. Proper lubrication and periodic adjustment can extend their operational life significantly without requiring complex repair work.

Types of Dovetail Slides

Manual Dovetail Slides

Manual dovetail slides provide precise, controlled movement using hand-operated mechanisms. These are commonly used in setups that require occasional adjustments or low-volume production processes, such as laboratory testing or small-scale machining.

Motorized Dovetail Slides

For applications requiring automation, motorized dovetail slides can be equipped with stepper motors, servo motors, or other drive systems. This enables smooth, automated positioning for CNC machines, assembly lines, and robotic systems.

Custom Dovetail Slide Solutions

Gilman Precision also specializes in designing custom dovetail slides tailored to unique application requirements. Whether you need specific travel lengths, mounting configurations, or load capacities, custom slides can be engineered to fit seamlessly into your equipment.

Applications of Dovetail Slides

CNC Machines and Milling Equipment

In CNC machining and milling, dovetail slides provide rigid and accurate movement for cutting tools and workpieces. Their strong support and precision-ground surfaces ensure reliable positioning for complex machining tasks.

Assembly and Automation Systems

Automation systems use dovetail slides for controlled linear motion in material handling, inspection stations, and assembly operations. Their durability and stability help improve system reliability and reduce downtime.

Industrial Equipment and Fixtures

Many types of heavy-duty industrial machinery rely on dovetail slides for stable and repeatable movement. From inspection fixtures to specialized manufacturing equipment, these slides ensure accurate motion in demanding environments.

Construction and Features of Gilman Dovetail Slides

High-Quality Materials and Precision Craftsmanship

Gilman Precision uses high-grade materials and advanced machining techniques to manufacture dovetail slides with superior dimensional accuracy. Precision scraping and grinding ensure smooth contact surfaces for stable motion without binding.

Adjustable Gibs for Tight Tolerance Control

Each dovetail slide is equipped with adjustable gibs that allow fine-tuning of fit and preload. This ensures optimal sliding performance, compensates for wear over time, and maintains precise alignment throughout the slide’s lifespan.

Lubrication Options for Smooth Operation

Gilman offers various lubrication options for dovetail slides, including grease fittings or oil ports, to reduce friction and enhance smooth operation. Proper lubrication extends the service life and maintains consistent performance under demanding conditions.

Customization Options for Dovetail Slides

Tailored Travel Lengths and Load Capacities

Every application has unique requirements, which is why Gilman provides custom dovetail slides with specific travel lengths, mounting patterns, and load ratings. This ensures the slide integrates seamlessly with your existing machinery and meets your exact motion control needs.

Integration with Motors and Controls

Custom dovetail slides can be equipped with motors, linear scales, or feedback systems for enhanced automation and precision. This allows seamless integration into CNC machines or automated production systems.

Maintenance and Service for Dovetail Slides

Prolonging Slide Lifespan

To ensure long-lasting performance, dovetail slides require periodic inspection, lubrication, and gib adjustments. Gilman Precision provides detailed maintenance guidelines and support to help customers maximize the life and accuracy of their slides.

Expert Rebuild and Repair Services

If slides become worn over time, Gilman offers rebuild and repair services to restore them to like-new condition. Services include resurfacing, gib replacement, and precision alignment adjustments to maintain original specifications.

Why Choose Gilman Precision Dovetail Slides

Decades of Experience in Motion Control

With over 70 years of expertise in precision engineering, Gilman Precision has a proven track record of manufacturing dovetail slides that meet the highest standards for quality and reliability.

Proven Quality and Performance

Each slide undergoes rigorous quality inspections, including accuracy checks and durability testing. This ensures that Gilman’s dovetail slides deliver consistent performance in even the most demanding industrial environments.

Custom Solutions and Technical Support

Gilman’s engineering team works closely with customers to design custom dovetail slides that fit specific applications. From concept to installation, Gilman provides the technical support needed for successful integration.

Enhance Linear Motion with Precision Dovetail Slides

When your operation requires reliable, stable, and accurate linear motion, Gilman’s dovetail slides are the ideal choice. Designed for heavy-duty use and built with precision craftsmanship, these slides improve machining accuracy, enhance automation performance, and extend the life of your equipment.

Whether you need standard models for general use or fully customized dovetail slides for specialized applications, Gilman Precision delivers solutions that combine durability, precision, and value for today’s demanding manufacturing environments.