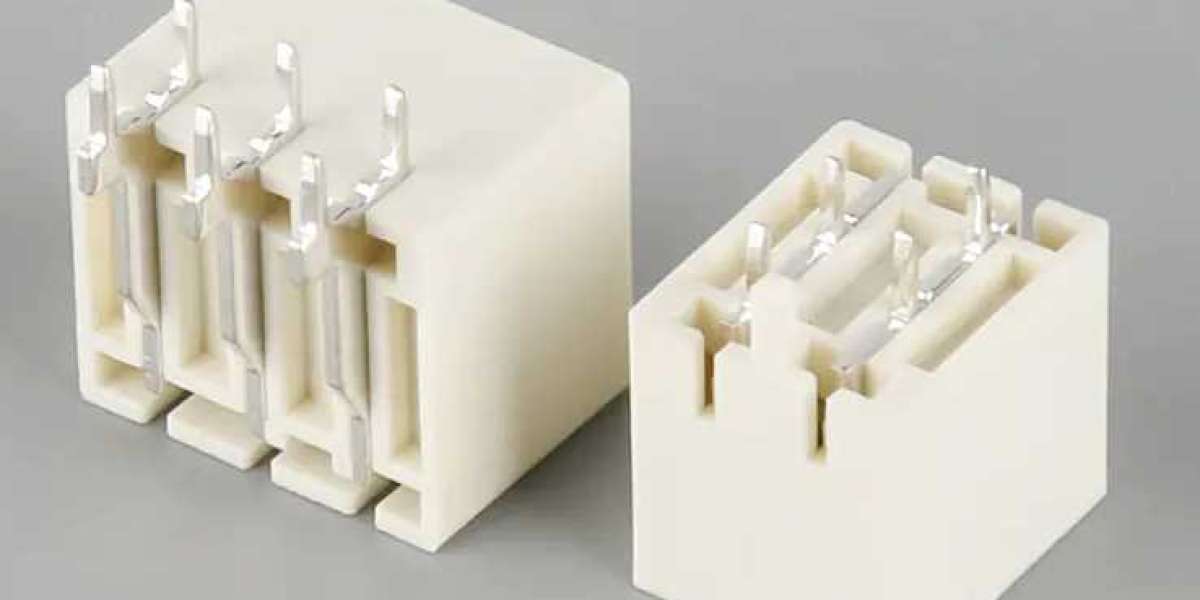

The RAST Series Connectors are widely used in various industries due to their reliability and performance. However, proper installation and maintenance are essential to ensure the connectors function effectively over time. In this article, we will explore the best practices for installing and maintaining RAST Series Connectors to maximize their longevity and reliability.

When installing RAST Series Connectors, it is crucial to follow the manufacturer's guidelines to ensure a secure and efficient connection. Start by ensuring that the environment where the connector will be installed is clean and dry, as dust, moisture, or contaminants can interfere with the connector’s performance. It is also important to check that the connector pins align correctly with the corresponding sockets. Misalignment can lead to connection issues and reduced reliability.

For some RAST Series Connectors, specific torque settings are recommended for securing the connections. Over-tightening or under-tightening can cause damage or prevent the connector from functioning as intended. Using the proper tools, such as torque wrenches or precision screwdrivers, will help achieve the correct tension. Additionally, it’s advisable to use contact grease or conductive lubricants when installing the connectors to reduce friction and ensure smooth operation.

Once the connectors are installed, regular maintenance is essential to ensure they continue to perform efficiently. Periodic inspections of the RAST Series Connectors should be conducted to check for signs of wear, corrosion, or contamination. Cleaning the connectors with a lint-free cloth or appropriate cleaning solutions can help remove dirt and prevent poor contact.

In environments with high moisture or exposure to harsh chemicals, consider using corrosion-resistant connectors or applying anti-corrosion coatings to extend their service life. Additionally, connectors should be checked for secure connections during routine system maintenance. Loose connections can lead to power loss or equipment failure, so it’s important to ensure that all connectors are firmly attached.

Proper installation and ongoing maintenance of RAST Series Connectors are key to ensuring their performance and reliability. By following the recommended installation practices and maintaining the connectors regularly, users can prolong their life cycle, reduce downtime, and avoid costly repairs or replacements. This approach contributes to more efficient and reliable operations in industrial, automotive, and electronic applications.