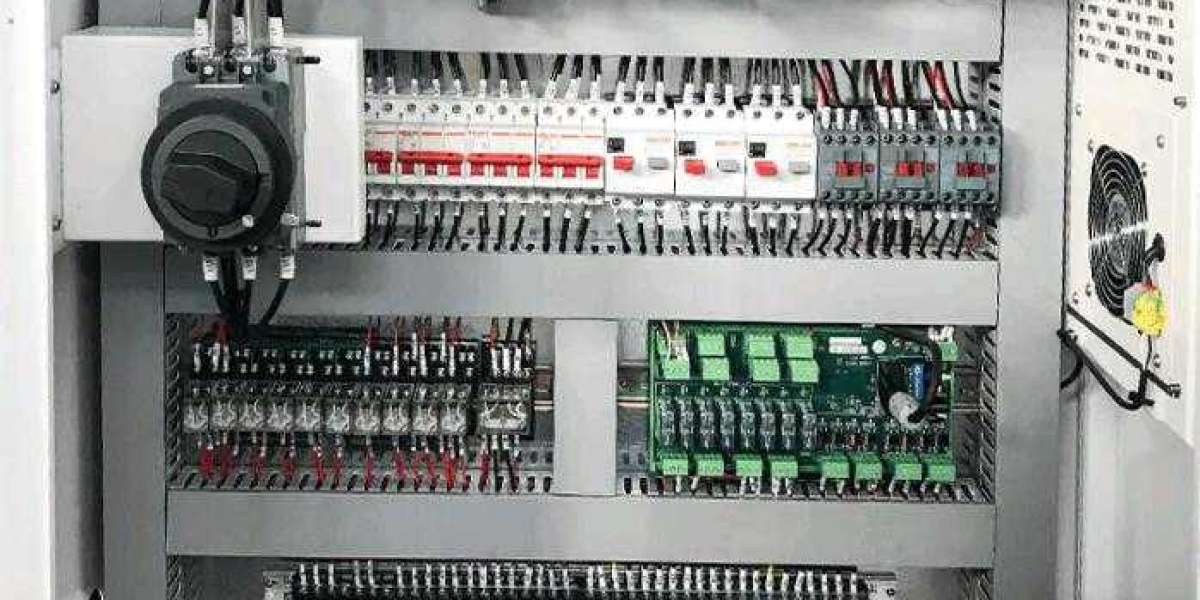

The control center of an automatic slant bed turning lathe plays a vital role in the machine's operation, coordinating and managing the various components to ensure precise and efficient machining. This sophisticated system integrates both hardware and software elements to guide the lathe through complex turning operations.

At the heart of the control center is the CNC (Computer Numerical Control) system. This system interprets the program instructions provided by the operator and translates them into actionable commands that control the machine’s movements. The CNC system is responsible for directing the movements of the tool turret, spindle, and other key components along the X, Y, and Z axes.

The operator interface is a critical part of the control center. It typically includes a display panel or touchscreen where the operator can input commands, monitor the lathe’s status, and adjust settings as necessary. Through this interface, operators can load machining programs, modify tool paths, and view real-time performance data. The interface is designed for ease of use, allowing operators to interact with the machine and make adjustments with minimal effort.

Another important feature of the control center is its ability to manage tool changes. The system can automatically switch tools in the tool turret based on the requirements of the machining process. This automation increases productivity by reducing downtime and minimizing the need for manual intervention.

Additionally, the control center monitors the machine’s performance by tracking key parameters such as spindle speed, feed rate, and cutting conditions. It can also detect potential issues or errors during the machining process, alerting the operator and ensuring smooth operation.

https://www.zjgycnc.com/product/slantbed-cnc-lathe/cnc-machine-full-automatic-slant-bed-turning-lathe.html

All lathes are integrally cast with 250 materials to ensure processing rigidity and machine tool integrity.

Independent spindles with stepless speed change, better smoothness, and suitable for different speed processing requirements of complex products.

The spindle is driven by a servo motor to ensure high torque output when the spindle is running at low speed. It also makes the spindle start and stop faster and the speed runs more smoothly.