In the fast-evolving packaging industry, manufacturers are paying closer attention to efficiency, sustainability, and production cost optimization. As global demand for lightweight, durable, and eco-friendly bottle caps continues to rise, the need for more advanced machinery has become critical. The discussion around production cost has also intensified, as businesses seek the perfect balance between technology investment and return. Within this dynamic, understanding the Cap Compression Molding Machine Price provides essential insight into how value, innovation, and performance align in modern cap manufacturing.

The demand for high-output and low-energy production systems has accelerated due to increasing competition and global sustainability goals. Traditional injection molding methods, while reliable, consume more energy and result in higher material waste. In contrast, cap compression molding machines utilize precise temperature control and direct compression processes that drastically reduce resin loss. This not only saves raw materials but also improves overall production efficiency. Such benefits have made compression technology a preferred choice for beverage, cosmetics, and pharmaceutical packaging companies seeking consistent quality at lower costs.

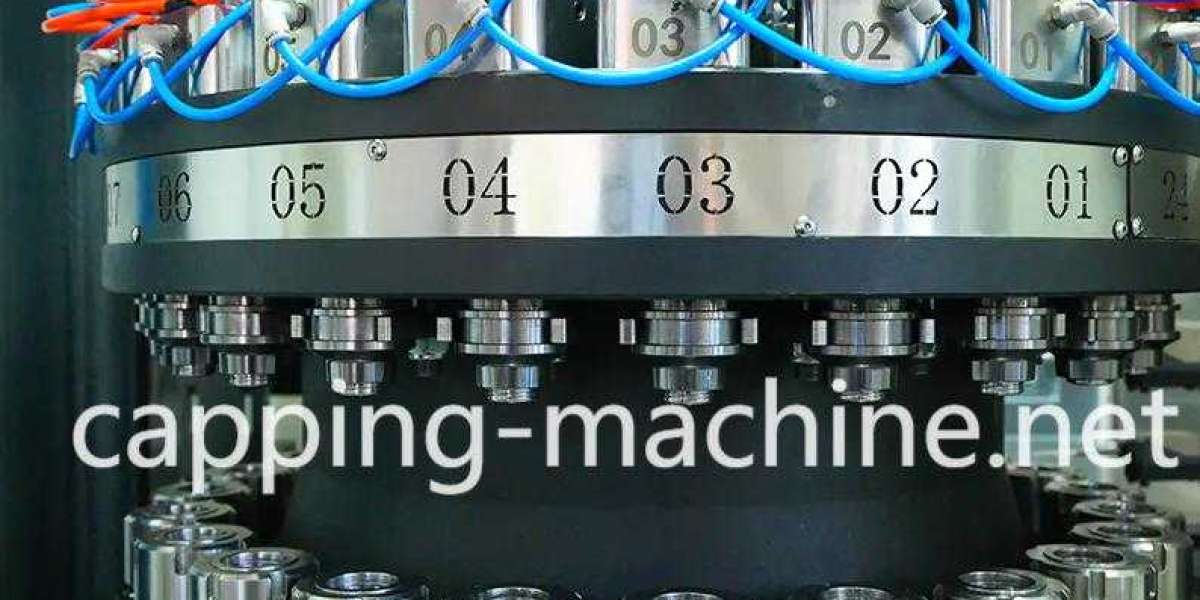

From a technological standpoint, the new generation of cap compression systems has reached remarkable levels of precision and automation. Manufacturers like Taizhou Chuangzhen Machinery Manufacturing Co., Ltd. have invested heavily in research and development, integrating servo-driven mechanisms, advanced PLC control systems, and real-time monitoring capabilities. These improvements enhance process stability while maintaining strict dimensional accuracy. For example, automated cavity temperature regulation allows consistent molding results even under high-speed operations, significantly minimizing defect rates.

Another major driver of adoption is energy efficiency. Compared to traditional methods, compression molding consumes less power per cap produced due to its shorter heating cycles and optimized mechanical layout. The machines are designed with energy recovery systems that reuse heat generated during operation, resulting in lower energy bills and reduced carbon footprint. For large-scale cap manufacturers, this represents not only environmental responsibility but also long-term cost savings that can dramatically improve profitability.

The applications of compression molding extend far beyond beverage closures. Today, this technology is being used for specialized caps and closures in the personal care, pharmaceutical, and household product sectors. Each of these industries demands different material properties, shapes, and performance characteristics. The flexibility of modern cap compression machines allows easy adjustment of mold designs and production parameters, enabling manufacturers to adapt quickly to evolving market trends and consumer preferences.

From a performance perspective, cap compression molding offers superior part integrity and consistent wall thickness compared to injection molding. Since the material is compressed rather than injected under high pressure, the polymer’s molecular structure remains uniform. This enhances the mechanical strength and sealing performance of the caps. Moreover, the process generates less internal stress, which reduces the risk of warping and cracking — critical factors for caps that must maintain airtight sealing in beverage and pharmaceutical applications.

For buyers and investors analyzing the market, understanding machine pricing involves evaluating more than just initial costs. Factors such as production capacity, energy efficiency, automation level, and maintenance requirements all influence the long-term value proposition. Leading suppliers like Taizhou Chuangzhen Machinery focus on providing scalable solutions that combine cost-effectiveness with high precision. The integration of modular design principles allows clients to expand capacity easily without full equipment replacement, offering a more economical pathway for growth.

Furthermore, the company’s technical support network and after-sales service ensure that customers receive maximum uptime and process reliability. This level of support plays a crucial role in determining real operational costs, often outweighing minor differences in purchase price. As more manufacturers transition toward sustainable production, they view modern compression systems not merely as equipment purchases, but as strategic investments in long-term efficiency and brand reputation.To explore technical details, machine specifications, and pricing insights related to cap compression molding technology, visit Taizhou Chuangzhen Machinery’s official resource page: https://www.capping-machine.net/news/industry-news/cap-compression-molding-machines-price-types-process-and-future-trends.html .