In the rapidly evolving packaging sector, manufacturers are under increasing pressure to balance production efficiency with environmental responsibility. The growing demand for lightweight, durable, and recyclable bottle caps has accelerated the shift toward advanced compression technologies, where the Cap Compression Moulding Machine stands as a key innovation driving transformation across the industry. With its ability to produce consistent, high-quality caps while minimizing material waste and energy use, this technology aligns with the market’s shift toward sustainable and precision-based manufacturing solutions.

As global beverage, pharmaceutical, and personal care industries expand, packaging standards are rising. Traditional injection moulding systems, while established, often fall short in speed and cost efficiency when compared with modern compression technology. Cap compression moulding offers advantages that directly address market needs — faster cycle times, reduced maintenance, and improved material utilization. These features not only lower operating costs but also support environmentally conscious production strategies, helping manufacturers meet increasingly strict sustainability targets without sacrificing performance or profitability.

One of the most notable innovations behind this technology is its energy-efficient design. By applying lower processing temperatures and optimized pressure control, compression moulding machines consume significantly less power than conventional systems. This efficiency contributes directly to reduced carbon emissions and aligns with global initiatives promoting energy conservation within industrial production. For manufacturers managing large-scale cap output, this technological shift represents both an economic and ecological advantage, offering long-term benefits for operational sustainability.

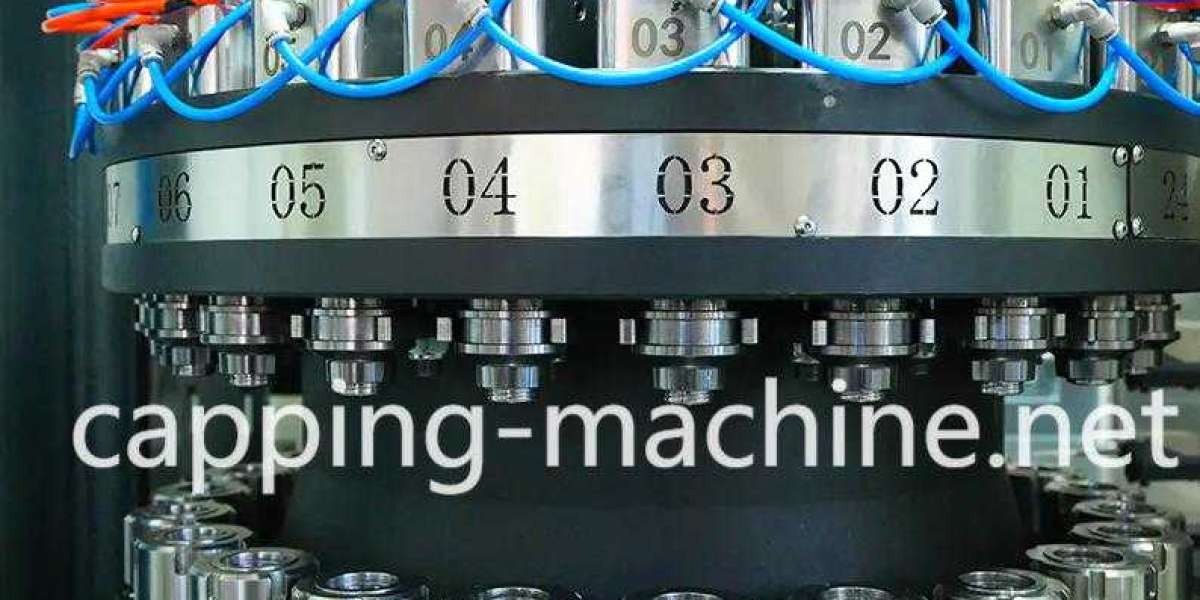

In addition to energy efficiency, precision control has become a defining feature of modern compression equipment. Using servo-driven systems and intelligent automation, these machines ensure every cap is formed with uniform thickness and flawless sealing performance. This precision is particularly valuable in the beverage industry, where sealing reliability affects both product quality and brand reputation. Moreover, advanced sensor systems and digital interfaces enable operators to monitor production metrics in real time, reducing human error and enhancing consistency across production runs.

Another crucial factor driving adoption is flexibility. Cap compression moulding systems can easily switch between different cap designs and resin types, making them ideal for manufacturers handling diverse product lines. This adaptability enables faster response to market changes, shorter lead times, and improved cost management in competitive industries. For brands aiming to introduce customized or specialized closures, the technology’s modular design allows for simple configuration adjustments without extended downtime or complex retooling.

The application scenarios for compression moulding technology extend beyond beverages. It has gained traction in healthcare packaging, where hygiene and dimensional accuracy are critical. The smooth interior finish of compression-moulded caps reduces contamination risk, ensuring compliance with pharmaceutical safety standards. Similarly, in the personal care sector, the ability to achieve intricate cap designs with consistent quality provides aesthetic and functional advantages that strengthen product appeal in retail markets.

Taizhou Chuangzhen Machinery, a leading manufacturer specializing in compression moulding systems, has continuously advanced its technology to meet these evolving demands. Their machines integrate smart control platforms, efficient hydraulic systems, and environmentally conscious designs tailored to various cap production needs. With a strong focus on innovation, durability, and user experience, the company provides solutions that align with the latest trends in intelligent and sustainable manufacturing.To explore more about Taizhou Chuangzhen Machinery’s range of compression moulding systems and learn how they are reshaping global packaging production, visit https://www.capping-machine.net/ .