Friction lining producers occupy a critical position in the global industrial and automotive supply chain. Their products, though often unseen by the average consumer, are essential to the safe and efficient functioning of vehicles, machinery, and heavy equipment. Friction linings are specialized materials applied to components such as brake pads, clutches, and industrial brakes. They provide the necessary resistance to motion, enabling controlled deceleration, stopping power, and torque transmission. Without them, modern transportation and manufacturing systems would be far less reliable and significantly more hazardous.Get more news about friction lining producer,you can vist our website!

The production of friction linings is a complex process that requires a blend of engineering expertise, material science, and strict quality control. Producers must carefully select raw materials, which often include fibers, resins, and fillers, to achieve the desired balance of durability, heat resistance, and frictional properties. Historically, asbestos was widely used due to its excellent heat tolerance, but health concerns led to its replacement with safer alternatives such as aramid fibers, ceramics, and advanced composites. Today, friction lining producers are at the forefront of developing eco‑friendly and non‑toxic materials that meet both performance and regulatory standards.

One of the defining characteristics of friction lining production is the emphasis on safety. Automotive manufacturers, for example, rely on friction lining producers to deliver components that can withstand extreme conditions—high temperatures, sudden loads, and repeated stress. Producers must adhere to rigorous testing protocols, including wear resistance, coefficient of friction stability, and thermal performance. These tests ensure that the linings will perform consistently over thousands of braking cycles, protecting drivers and passengers alike. In industrial applications, friction linings are equally vital, preventing machinery from overheating or failing during heavy operations.

Beyond safety, friction lining producers also contribute to efficiency and sustainability. Modern linings are designed not only to last longer but also to reduce noise, vibration, and dust emissions. This is particularly important in urban environments where air quality and noise pollution are pressing concerns. Producers are investing heavily in research and development to create products that minimize environmental impact while maximizing performance. For instance, copper‑free brake pads have become a major innovation, as traditional copper compounds can leach into waterways and harm aquatic life. By eliminating harmful substances, producers demonstrate their commitment to sustainable manufacturing.

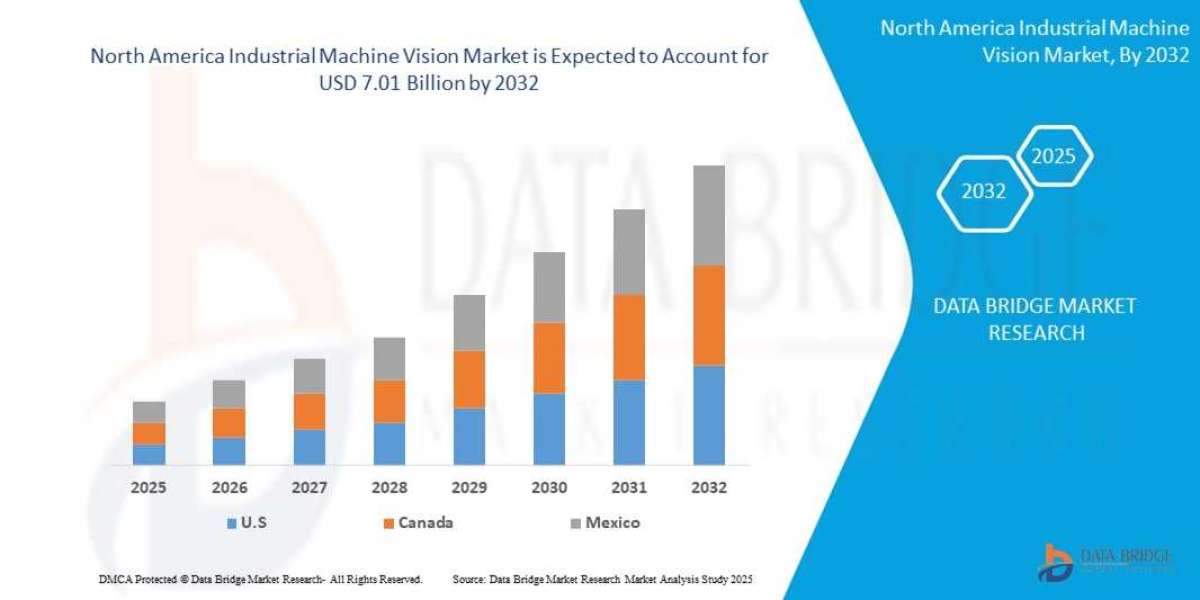

The global market for friction linings is highly competitive, with producers spread across regions such as Asia, Europe, and North America. Each region has its own strengths: Asian producers often focus on cost‑effective mass production, European companies emphasize precision engineering and environmental compliance, while North American firms balance innovation with large‑scale distribution. This diversity fosters healthy competition and drives continuous improvement in product quality. At the same time, producers must navigate challenges such as fluctuating raw material prices, evolving regulations, and the growing demand for electric vehicles, which require different braking and transmission systems.

Electric mobility presents both challenges and opportunities for friction lining producers. On one hand, regenerative braking systems in electric vehicles reduce reliance on traditional friction brakes, potentially lowering demand. On the other hand, these vehicles still require friction linings for emergency braking and specific driving conditions. Producers are adapting by designing linings that complement regenerative systems, ensuring smooth transitions and reliable backup performance. This adaptability highlights the resilience of the industry and its ability to evolve alongside technological shifts.

In conclusion, friction lining producers are indispensable players in the modern industrial landscape. Their work ensures that vehicles stop safely, machinery operates reliably, and industries continue to function efficiently. By combining material innovation, safety standards, and sustainability practices, they not only meet current demands but also anticipate future challenges. As transportation and manufacturing continue to evolve, friction lining producers will remain central to progress, quietly enabling the motion and safety of our daily lives.