Every engineer knows the sinking feeling when a valve unexpectedly fails during operation. Production slows. Maintenance rushes to the scene. The root-cause analysis takes time. And eventually, everyone concludes the same thing: “Something inside gave out.”

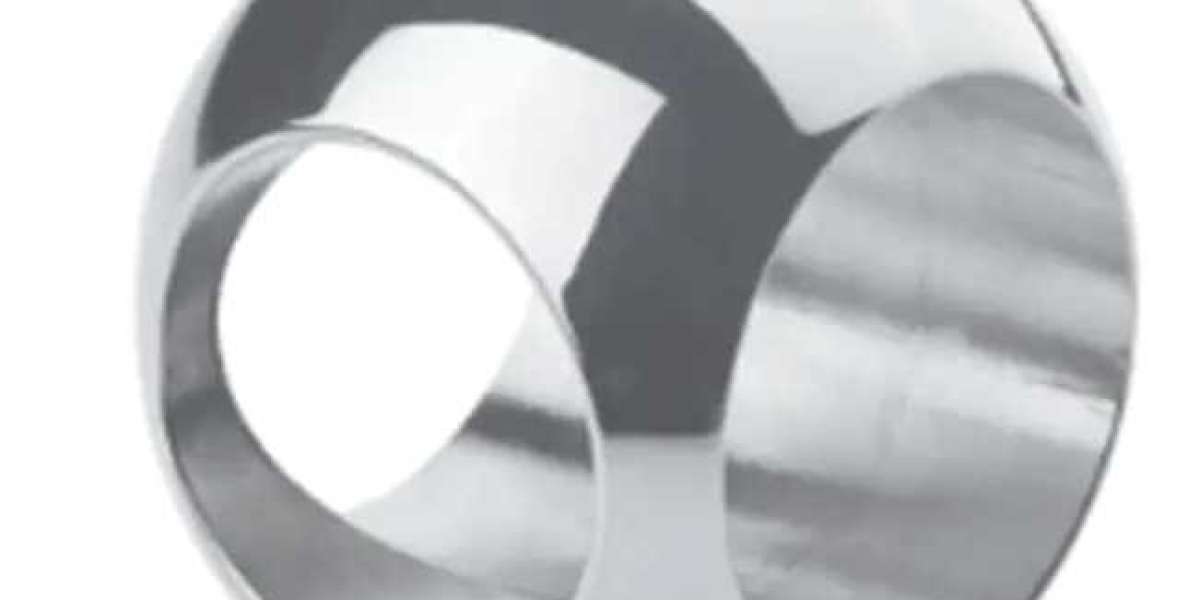

Quite often, that “something” is the Ball Valve Ball or Hard Seal Ball, which silently works under high stress every day.

Old Experience:

You replace entire valves when only one internal part is failing.

Your maintenance team handles repeat issues in the same zones.

You’ve normalized periodic failures because “that’s just how it is.”

But these patterns drain time, energy, and resources.

New Experience:

The valve stays stable for longer stretches.

Your maintenance schedule becomes more predictable.

Teams stop revisiting the same trouble points.

Unexpected failures become rare rather than routine.

This shift happens when the heart of the valve—the internal ball—can withstand large fluctuations, aggressive media, and constant cycling. Better Ball Valve Balls and Hard Seal Balls don’t shout their presence; they simply stay reliable in moments when weak components usually collapse.

Users often say the upgrade feels like removing a constant background worry. The system runs smoother. The maintenance board is less cluttered. And the operations team gains time to focus on improvements instead of repeated fixes.

Since the ball integrates into your current valve setup, the transition is effortless. No new procedures, no rethinking pipelines—just a stronger internal component supporting the workflow you already trust.

Sometimes preventing failure is simply about strengthening the right piece.