Understanding PP-R Inserts

PP-R inserts are components used in piping and plumbing systems to reinforce joints, enhance sealing, and improve overall system durability. Made from polypropylene random copolymer (PP-R), these inserts provide stability, prevent leaks, and allow for more secure connections between pipes and fittings. They are widely used in residential, commercial, and industrial piping systems.

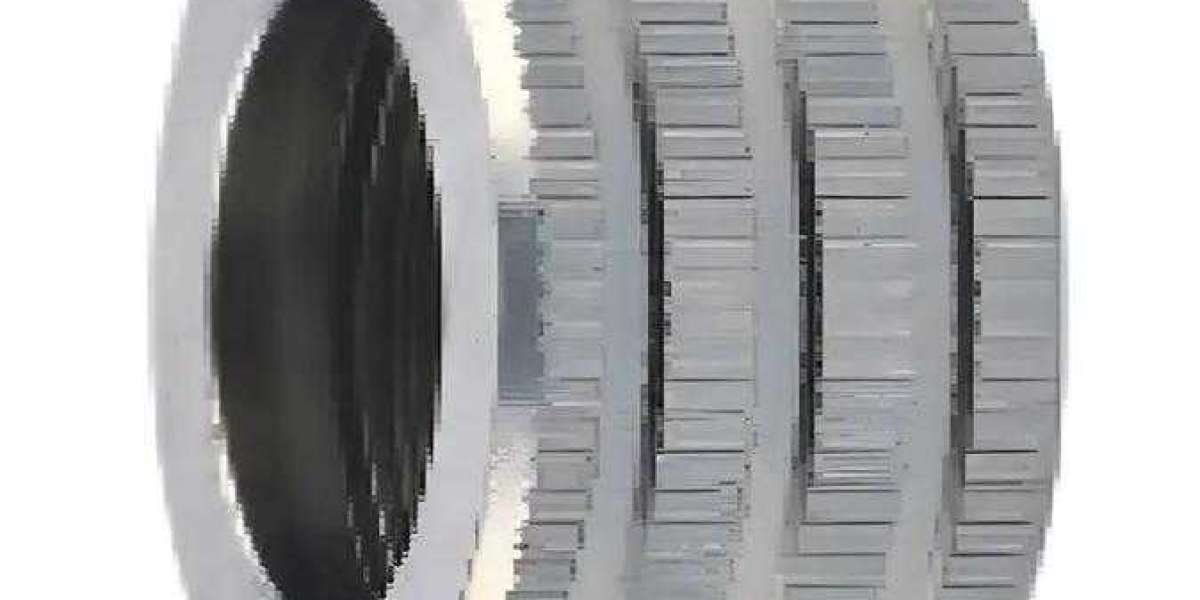

Materials and Design Considerations

PP-R inserts are made from high-quality polypropylene random copolymer, often reinforced for additional strength. The material is chosen for its resistance to heat, pressure, and chemical corrosion, making the inserts suitable for both hot and cold water systems. Proper design ensures accurate fitting, reliable sealing, and long-term durability under operational stresses.

Manufacturing Processes for Precision

Manufacturing PP-R inserts involves precision molding techniques such as injection molding or extrusion. These processes ensure dimensional accuracy, smooth surfaces, and proper internal structures for optimal sealing. Heat treatment or annealing may be applied to enhance mechanical properties and ensure stability under pressure.

Installation and Maintenance

PP-R inserts are typically installed inside pipes or fittings to provide reinforcement and prevent leaks. Installation is straightforward but requires proper alignment and pressure testing to ensure effectiveness. Routine inspection ensures the inserts remain intact, and the system continues to perform reliably.

Customization for Specific Applications

Many suppliers offer PP-R inserts in various sizes, shapes, and reinforcement levels to meet specific project requirements. Custom options allow engineers and contractors to adapt inserts for unique piping layouts, temperature conditions, or pressure ratings. Tailored solutions improve system performance and reduce maintenance issues.

Applications Across Industries

PP-R inserts are used in residential plumbing, commercial water supply systems, industrial piping, heating systems, and chemical transport pipelines. Their ability to maintain leak-proof connections under various pressures and temperatures makes them essential for safe and reliable fluid transportation.

Benefits of Using PP-R Inserts

Using high-quality PP-R inserts enhances joint strength, prevents leaks, reduces maintenance costs, and prolongs the lifespan of piping systems. Their chemical and thermal resistance ensures reliability across a wide range of applications, making them an efficient and durable choice for modern piping systems.

Choosing the Right Supplier

Selecting a reputable supplier ensures that PP-R inserts meet high-quality standards, provide consistent performance, and comply with industry regulations. Experienced manufacturers offer precise production, customization options, and technical support, helping buyers implement durable and reliable piping solutions.