SMC Mould is widely used in industries that rely on composite materials for structural strength and stable dimensions. It works with Sheet Molding Compound, a material supplied in sheet form that already combines fibers, resin, and additives. This setup allows factories to shape large or complex components under controlled heat and pressure.

Many buyers start researching SMC Mould when their products require rigidity and corrosion resistance at the same time. Automotive body panels, electrical enclosures, and industrial housings are common examples. These parts often need to hold their shape under stress, and SMC material performs well in that role when paired with the right mold design.

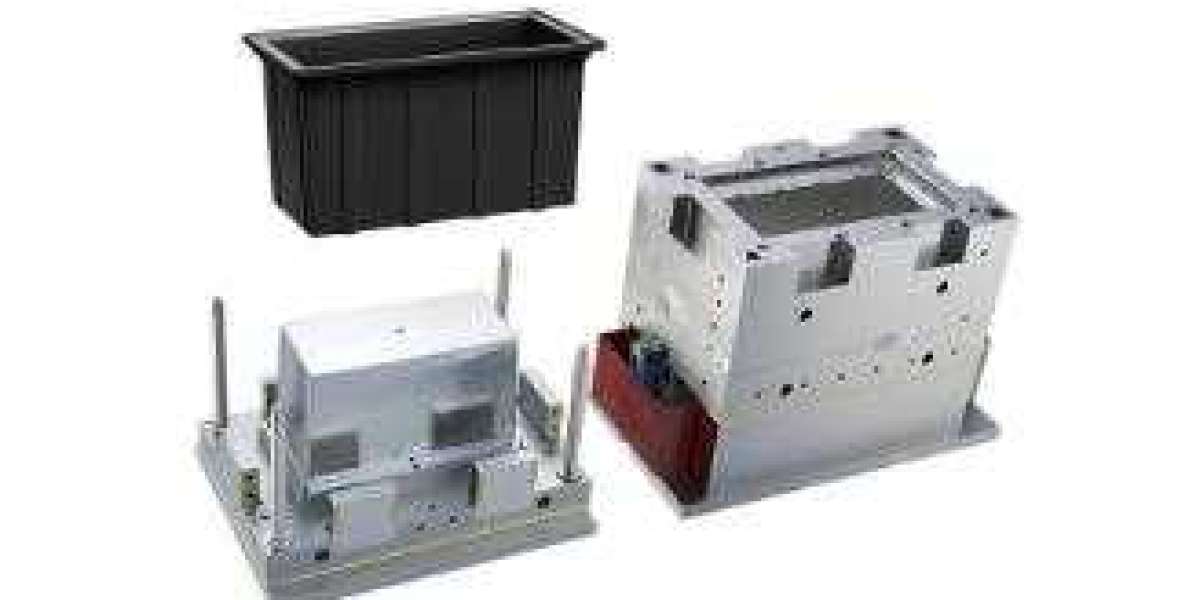

One common question is how SMC Mould differs from BMC tooling. The main difference comes from how the material behaves during processing. SMC is placed into the mold as pre-cut sheets, then compressed. This means the mold must handle high pressure while guiding material flow evenly across large surfaces. That requirement directly affects mold structure and venting design.

Factories also care about surface detail. An SMC Mould can reproduce textures and shapes accurately when temperature and pressure are controlled properly. This helps reduce extra finishing work after demolding, which matters when production schedules are tight, and labor planning needs to stay predictable.

When evaluating SMC Mould Manufacturers, buyers usually look beyond the mold itself. Experienced suppliers often assist with early design discussions, including part thickness, rib layout, and material placement. This input helps prevent uneven flow or trapped air during compression, which can affect part appearance and consistency.

Production stability is another frequent concern. An SMC Mould is built to handle repeated cycles at elevated temperatures. Consistent mold heating and controlled compression support uniform curing across parts. This is important for factories supplying components to downstream assembly lines where variation can cause delays.

Some buyers also ask whether SMC Mould fits automated or semi-automated production. In many cases, it does. Once the mold and process parameters are set, sheet loading, compression, and demolding can follow a repeatable rhythm. This supports steady output without frequent adjustments.

Environmental considerations also influence decision-making. SMC material is supplied with controlled resin content, which helps limit excess material during molding. For factories aiming to manage waste more effectively, this aspect fits well with long-term production planning.

Comparing suppliers often comes down to experience with similar applications. SMC Mould Manufacturers who understand automotive, electrical, or industrial standards can align tooling details with real production needs. Their familiarity with pressure control, heating systems, and venting layout helps reduce trial cycles during ramp-up.

For factories searching online for SMC Mould and SMC Mould Manufacturers, the goal is practical clarity. Knowing how the mold works, where it fits, and how suppliers support production decisions makes it easier to move from inquiry to stable manufacturing without unnecessary back-and-forth.