Key Components of a Submersible Pump

A submersible pump comprises various components that work in unison to pump water efficiently from deep wells or other submerged areas. Understanding the breakdown of these components is essential for maintenance and repair tasks, ensuring the pump operates seamlessly.

Step-by-Step Guide: Dismantling a Submersible Pump

When it comes to dismantling a submersible pump, following a systematic approach is crucial to avoid damage and safely disassemble the pump for inspection or repair purposes. Here is a comprehensive guide on how to dismantle submersible pump:

- Disconnect Power: Before beginning the dismantling process, ensure the pump is disconnected from the power source to prevent any electrical hazards.

- Remove Pump from Well: If the pump is installed in a well or submerged area, carefully lift the pump out of the water to a suitable work area.

- Release Pressure: If the submersible pump is under pressure, release the pressure by opening the system's discharge valve to avoid any sudden bursts during disassembly.

- Detach Electrical Connections: Disconnect all electrical connections to the pump to ensure safety and prevent any electrical accidents.

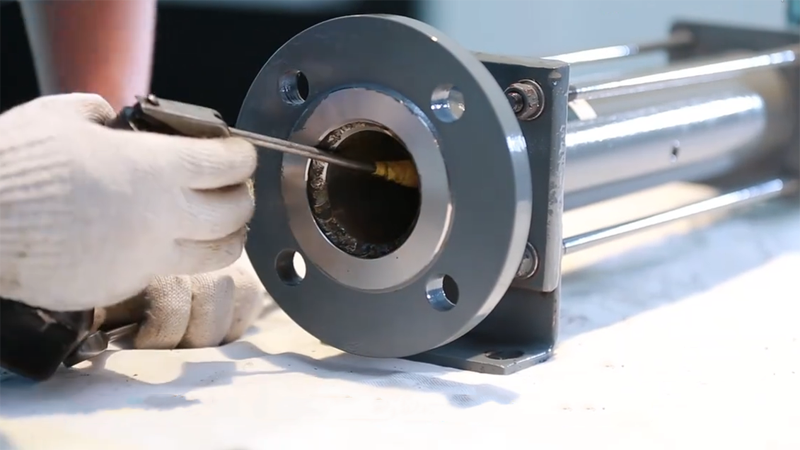

- Remove Pump Components: Start by removing the pump's outer casing, impeller, diffuser, motor housing, and other internal components carefully, keeping track of each part for reassembly.

- Inspect Components: Once the pump is dismantled, inspect each component for wear, damage, or blockages that may affect the pump's performance.

- Clean and Service: Clean the components thoroughly and perform any necessary servicing or repairs before reassembling the pump.

- Reassemble Pump: Carefully reassemble the pump, ensuring each component is correctly positioned and secured to maintain optimal performance.

- Test Operation: After reassembly, test the submersible pump's operation to ensure it functions correctly and efficiently.

Importance of Proper Maintenance and Disassembly

Maintaining and periodically disassembling a submersible pump is essential for prolonging its lifespan, optimizing performance, and preventing unexpected breakdowns. By following proper procedures and guidelines for dismantling and servicing, you can identify potential issues early and address them promptly.

Safety Precautions during Disassembly

When dismantling a submersible pump, safety should always be a top priority. Here are some safety precautions to keep in mind:

- Wear Protective Gear: Use appropriate personal protective equipment (PPE) such as gloves, safety glasses, and clothing to prevent injuries.

- Work in a Well-Ventilated Area: Ensure adequate ventilation in the workspace to prevent exposure to fumes or gases that may be released during disassembly.

- Use Proper Tools: Utilize the correct tools and equipment for disassembling the pump to avoid damage to components or injury to yourself.

- Follow Manufacturer Guidelines: Refer to the pump manufacturer's disassembly instructions and guidelines to ensure proper dismantling and reassembly procedures.

By adhering to safety protocols, following a methodical dismantling process, and conducting regular maintenance, you can keep your submersible pump in optimal condition for efficient water pumping operations.