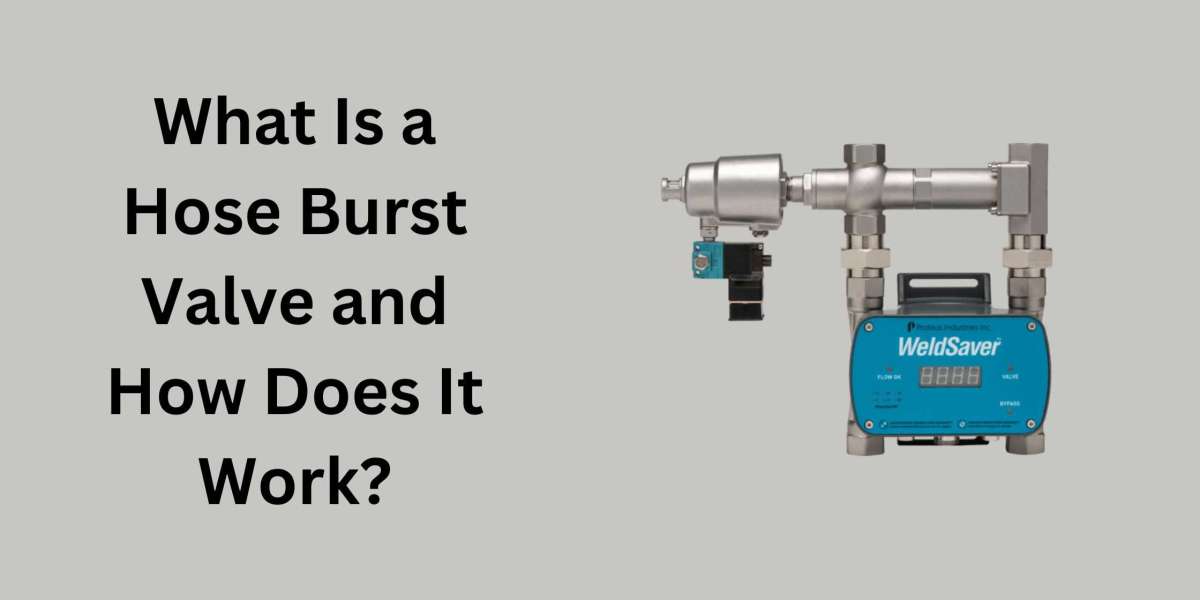

A hose burst valve, also known as a velocity fuse or hose rupture valve, is a crucial safety component used in hydraulic systems. It prevents sudden and uncontrolled fluid loss during a hose failure. When a hydraulic hose bursts or experiences a sudden pressure drop, the valve automatically shuts off the flow of hydraulic fluid, minimizing potential damage, preventing equipment failure, and enhancing operator safety. Hose burst valves are commonly used in construction machinery, lifting equipment, and industrial applications where hydraulic systems operate under high pressure.

What Is a Hose Burst Valve?

A hose burst valve, a velocity fuse or load-holding valve, is a hydraulic safety device installed in hydraulic systems to restrict or stop fluid flow when a hose ruptures. It is commonly used in applications involving heavy machinery, lifting equipment, and mobile hydraulics to prevent sudden and dangerous movements caused by hydraulic failures.

How Does a Hose Burst Valve Work?

A hose burst valve operates based on pressure and flow rate monitoring. Here’s how it works:

- Regular Operation: Under normal conditions, hydraulic fluid flows freely through the valve, allowing the system to function as intended.

- Detecting a Burst: If a hose bursts or leaks, the fluid flow increases drastically, creating a sudden pressure drop.

- Automatic Closure: The valve detects the rapid change in flow and pressure, triggering an internal mechanism (such as a spring-loaded poppet or a spool) to close the passage.

- Stopping Fluid Flow: Once closed, the valve prevents further hydraulic fluid loss, minimizing damage and potential hazards.

- Manual Reset or Controlled Release: Some hose burst valves require manual resetting after activation, while others have a controlled bypass function to allow slow fluid release.

Key Benefits of a Hose Burst Valve

- Enhanced Safety: Prevents sudden and dangerous movements of hydraulic equipment in case of hose failure.

- Equipment Protection: Reduces damage to hydraulic components by stopping fluid loss.

- Environmental Protection: Prevents hydraulic fluid spills, reducing ecological contamination.

- Compliance with Safety Regulations: Many industries require these valves to meet safety standards.

Choosing the Right Hose Burst Valve

When selecting a hose burst valve, consider factors such as:

A hose burst valve is a crucial safety component in hydraulic systems, preventing uncontrolled fluid loss and potential damage during a hose failure. Selecting the correct valve requires careful consideration of several factors to ensure optimal performance and system protection.

1. Understanding the Function of a Hose Burst Valve

A hose burst valve is designed to detect a sudden surge in flow caused by a hose rupture and instantly shut off the hydraulic fluid supply. This prevents uncontrolled movement of machinery, protects workers, and minimizes environmental hazards. Without a proper valve, a burst hose can lead to catastrophic system failure, damaging equipment and surroundings.

2. Determining the Flow Rate and Pressure Requirements

One of the most critical factors in choosing a hose burst valve is matching it to the hydraulic system’s flow rate and pressure. Valves are designed to operate within specific flow ranges, and selecting the wrong one can lead to false triggering or failure to activate when needed. It's essential to check the system’s operating pressure and flow characteristics to ensure compatibility with the chosen valve.

3. Selecting the Right Valve Size

Hose burst valves come in different sizes to fit various hose diameters and flow capacities. Using a too small valve can restrict fluid flow and reduce system efficiency, while an oversized valve may not detect bursts accurately. Carefully matching the valve size to the hydraulic hose specifications ensures proper operation and protection.

4. Considering the Installation Location

The placement of the hose burst valve within the hydraulic circuit is crucial for adequate protection. It should be installed close to the actuator or load-holding device to minimize the risk of uncontrolled movement if a hose fails. Proper positioning ensures a quick response and prevents excessive fluid loss.

5. Evaluating Material and Durability

A hose burst valve's durability is essential, as it operates in high-pressure and sometimes harsh conditions. Valves made from strong materials like stainless steel or high-quality alloys offer better resistance to corrosion, wear, and extreme temperatures. Choosing a valve with a long lifespan reduces maintenance costs and ensures continuous system protection.

Conclusion

A hose burst valve is an essential safety component in hydraulic systems, preventing uncontrolled fluid loss and protecting machinery and operators. By understanding how it works and choosing the correct valve for your application, you can enhance the reliability and safety of your hydraulic equipment. Investing in high-quality hose burst valves provides compliance with safety regulations and reduces the risk of accidents, making it a vital part of any hydraulic system.